Hair follicles from the 3D printer – what can you expect?

Preface

Dear Readers,

Medical research is progressing and there are always new, promising developments that could also help people for whom no therapy has been available so far. Especially in the field of hair loss with androgenetic alopecia as the cause, the technique of 3D printing of hair follicles has been prominent in recent times. This means that hair follicles as hairforming organs of the scalp can be automatically “printed” in the laboratory in order to replenish scalp surfaces affected by hair loss. It is hoped that “printed” hair follicles will be available in almost unlimited numbers, will be extremely inexpensive to produce and can be transplanted without the risk of a rejection reaction. Should these hopes materialize, androgenetic alopecia would be fully treatable. This may sound rather abstract, but on closer inspection it turns out to be a future method which, like all scientific methods, still has to undergo an intensive research and establishment process. Hence, there is still a long way to go before the hope for hair follicles from the 3-D printer in the form mentioned above will be fulfilled.

In this article I would like to introduce you to this exciting topic of 3D printing of organs and hair follicles in particular. First, we will explain how printing technology has made it into medical research and on what principles it is based. Then we will focus on what the technology can do to create a “natural” hair follicle in a 3D printer. We will then examine these requirements in the light of current publications on the subject in order to examine what has happened in recent years in the field, where the technology currently stands and what developments can possibly be expected in the coming years.

Therefore, enjoy reading!

Sincerely

Yours, Angela Lehmann

From letterpress printing to the development of 3D printers in medicine

In order to understand how the idea of producing human organs, including hair follicles, in a 3D printing process came about, it is first necessary to consider the beginnings of printing technology: In the Middle Ages, the knowledge was recorded in books and encyclopaedias and passed on to posterity. However, such books could only be reproduced by copying them by hand. This only changed in Europe with the invention of printing by Johannes Gutenberg in the 15th century. The fundamental principle of printing has not changed until the 20th century: Colour is transferred from a printing plate to a twodimensional plane, the paper. Since the 1980s, processes have been developed in industry that not only allow the transfer of material in two dimensions (length and width), but also allow printing in height. In general, such processes are referred to as 3D printing.

Small 3D printers work according to the following principle: The object to be produced is divided into different layers by a software. The 3D printer essentially consists of a plate, which forms the basis for the workpiece, a print head, which can be moved in all spatial dimensions via a linkage, a material feed, often using plastics, and an interface to the computer. The print head is initially heated so that the plastic is liquefied. Then the head moves to the first point of the bottom layer, releasing some print material that solidifies as it cools, then the print head moves to the next point and dispenses material again. When one layer is finished, the print head moves up a bit (or the base plate moves down) and the next layer begins. Depending on the printer model, material and filling of the workpiece, any 3-D objects can be printed in just a few minutes or hours.

Today, 3D printers can work with a wide variety of materials and are used to produce small plastic parts in households as well as for building houses, where foundations and walls can be printed from much larger 3D printers (e.g. Sakin & Kiroglu, 2017). However, 3D printing technology has also attracted attention in the medical field: here it is not a question of the particularly largescale processes, but of small size. Ideally, it should be possible to arrange individual specialized cells into tissues using the 3D printing process and these in turn into whole organs. This procedure is also known as 3D bioprinting and has been considered a promising method since the beginning of the 21st century to counteract the constant shortage of donor organs and to provide people suffering from lifethreatening diseases with a new heart, kidneys or lung, for example. The latest results show that the technology, which sounded like science fiction 10 years ago, is making rapid progress: In 2019, Israeli researchers succeeded in producing a heart from the 3D printer based on human tissue. Although the printed heart is considerably smaller than a real heart and cannot yet beat in a coordinated manner, all the physiological structures (i.e. vessels, muscles and nerves) required for this are present (Noor et al., 2019). These results have been taken up by the press worldwide and mark a major advance in personalized regenerative medicine.

If this method is successful, the 3-D pressure of any organ would be possible. This also includes human hair follicles, which are frequently lost due to androgenetic alopecia as a form of hair loss. Therefore, the following section will examine how far the technique of medical 3-D printing has progressed regarding hair follicles.

Human hair follicles from the 3D printer

Basics

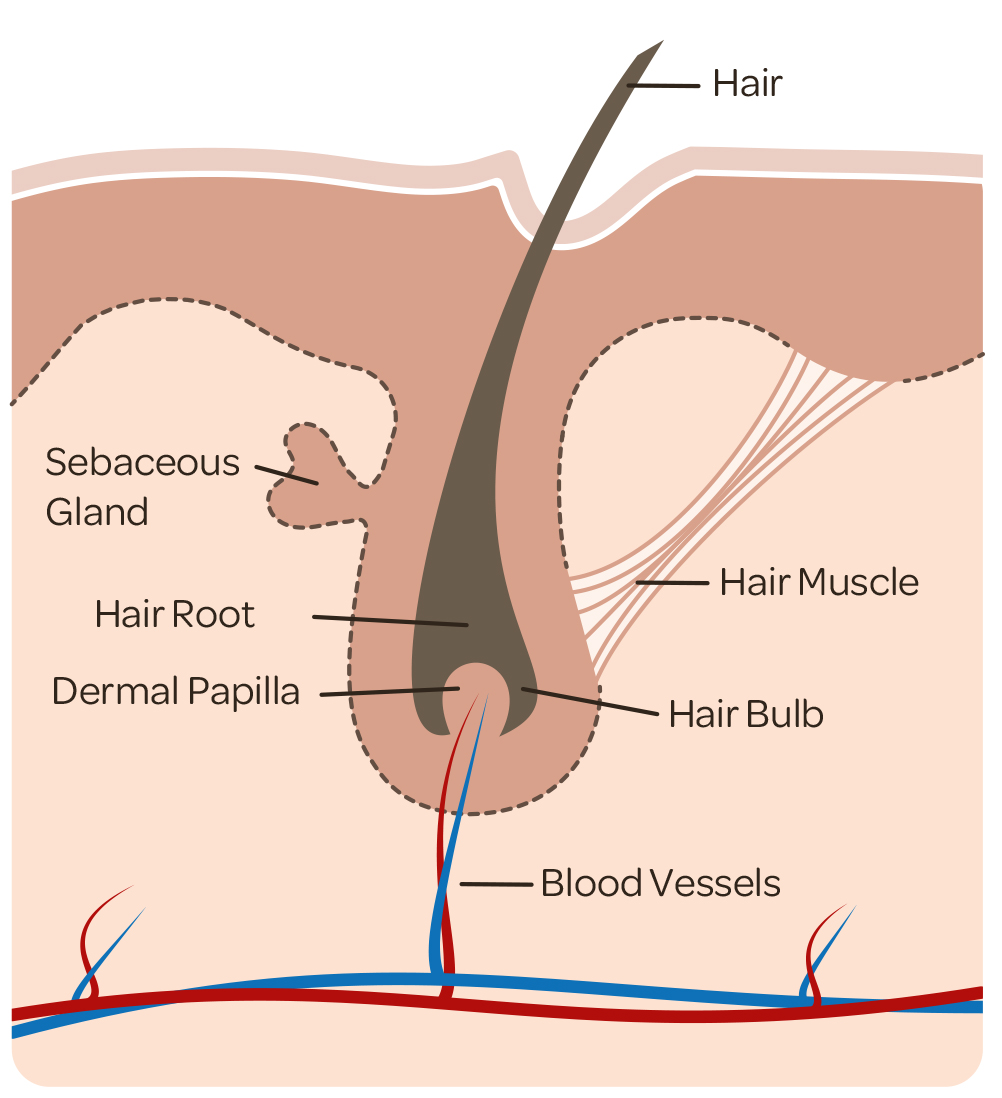

Like a heart or kidney, a hair follicle is an organ of the human body consisting of different cell types that fulfill different tasks. Hair follicles can also be described as hair-forming organs. In humans, the hair follicles are embedded in the skin and are not visible from the outside. On the other hand, the hair formed by them is visible, which we model, style or dye in the head area and, thus, create an expression of the personal individuality. The schematic structure of a hair follicle is shown in the following illustration.

Figure 1: Structure of a hair follicle

The figure shows that different structures are involved in the formation of a hair follicle, which must be present for the follicle to be able to form a visible hair. Androgenetic alopecia results in a hormonal loss of active hair follicles, so that less hair grows on the scalp.

3D printing a hair follicle must therefore be based on the principle that the specialized cells, which form the hair papillae, supplying blood vessels and the other necessary structures, are assembled in three-dimensional space in such a way that the individual cells and tissues remain in place. Ideally, the finished hair follicle is then ready for transplantation and produces hair as stable as a physiologically grown follicles would.

Current research in 3D printing hair follicles

The fact that considerations were made to use 3D printing methods for the production of hair follicles was largely due to two results: First, attempts were made to stimulate the activity of the follicles in the skin regions affected by alopecia by isolated autologous stem cells. However, this did not produce any stable results, since the implanted stem cells differentiate further, partly migrate away from the implantation site and thus the hair-forming activity is lost again. The other important finding was that even if it was possible to clone hair follicles from human stem cells in a test tube and implant them into hairless mice, the resulting hair growth did not follow a specific direction. Even hair that did not grow into the skin came out at completely different irregular angles, which is – among other things – aesthetically unacceptable (Gnedeva et al., 2015). From these two results it was concluded that the cells involved in the hair follicle had to follow a fixed spatial arrangement for hair production to occur and that the arrangement had to be maintained after implantation in order for the resulting hair growth to be stable.

Hence, researchers all over the world focused on the question of how hair follicles could be produced that firstly remain stable in their spatial arrangement and secondly also produce hair whose growth direction can be precisely determined. A suggestion for the solution of this problem is seen in scaffolds. These are small supporting structures to which the cells of the follicle can be attached and which, at best, can later be transplanted without problems. In this way, the cells of the follicle are in close spatial contact all the time and can thus exchange messenger substances that stimulate hair growth.

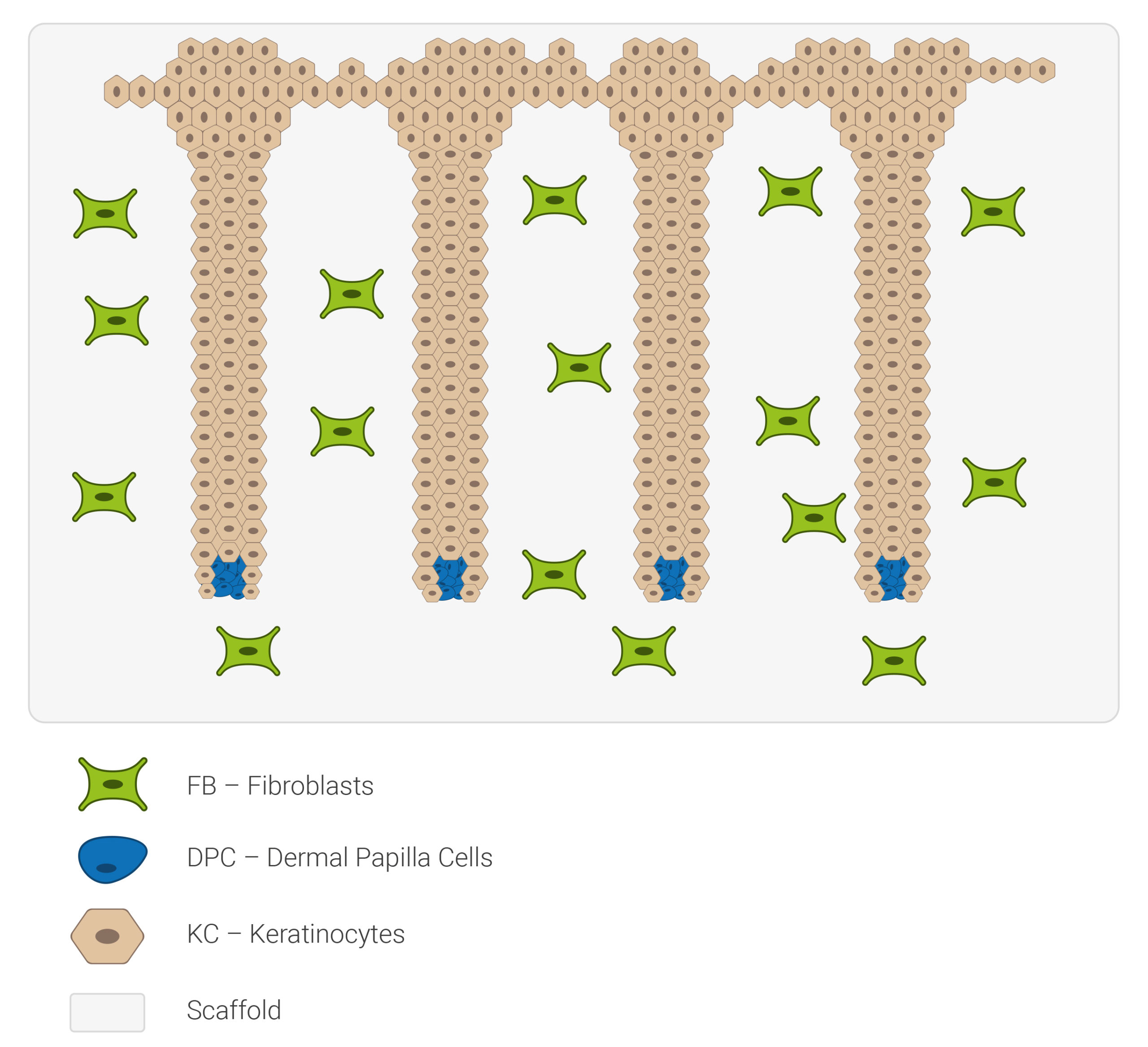

A success with this approach was achieved in 2018 by the working group led by Abaci et al. (2018). In order to keep the individual cells of the hair follicle in their spatial structure, they were inserted into a scaffold from the 3D printer. In this case, the scaffold consists of dermal fibroblasts (connective tissue cells) embedded in a scaffold material. The scaffold contains 4 mm long cavities with a diameter of 0.5 mm. The researchers then placed cells that were able to form a hair papilla in these cavities. Subsequently, the cavities in the scaffold were filled with keratinocytes (cell type of the epidermis) (see following figure).

Figure 2: Arrangement of cells necessary for 3D print hair follicles

However, the spatial arrangement of the cells alone was not sufficient to enable hair production or was it considerably weaker than expected. For this reason, the researchers stimulated special genes in the cells that are associated with hair production, which led to a significant increase in hair production. For transplantation into a living organism, the printed hair follicles had to be supplied with nutrients and oxygen via blood vessels. This was also achieved using the printing process by embedding fibroblasts and cells responsible for the formation and growth of blood vessels (venous endothelial cells) in the human organism into the scaffold structure. The skin constructs with dermal papillae produced in this way were then implanted in naked mice, where hair growth took place. This experiment was able to demonstrate that it is possible to spatially “reconstruct” a human hair follicle from individual cell types, which also exhibits stable hair growth after transplantation (Abaci et al., 2018).

The US company Organovo, which applied for a patent for 3D printed hair follicles in 2019, went one step further. This patent covers the technique with which hair follicles can be printed, which is similar to the approach of Abaci and colleagues (2018): Different cell types that are responsible for the production and maintenance of a hair papilla are stored together with signal substances and other biological components in a scaffold. In the case of Organovo, the scaffold consists of a flexible hydrogel. In contrast to previous experiments, in which almost all steps were carried out manually, Organovo’s approach is based on the automation of the printing process, in which several cell types can be inserted into the scaffold in a single printing process. In addition, the resulting hair follicles should also be ready for implantation in humans. Currently, however, no information is available as to whether Organovo has conducted successful experiments with human subjects or whether the patent only covers the right of implantation of the printed follicles (Patent No.: US 2019 / 0275208 A1).

Realistic evaluation of the current research process

As the discussed examples show, the development to produce artificial hair follicles is progressing rapidly. It took less than ten years from the finding that the spatial arrangement of the cells in a follicle is of critical importance for hair formation to the invention of an almost fully automated process for the production of such follicles.

Great hopes are attached to printed hair follicles, because so far the sustainable therapy of androgenetic alopecia as the most common form of human hair loss has been limited to removing hair follicles from an available donor area and transplanting them into the hairless recipient area as part of an autologous hair transplant. While there are two drugs approved to slow hair loss, they cannot stop or reverse hair loss. Therefore, there is a great need for possibilities to artificially produce hair follicles that would be suitable for transplantation.

To produce these artificial hair follicles, cells would be taken from patients interested in treatment with printed hair follicles. Either these are already stem cells or other cells (e.g. from blood) can be reprogrammed into stem cells in the laboratory. This has the great advantage that artificially printed hair follicles are not subject to any rejection reaction, so that the procedure would be available to everybody. The automation of the printing process, as described in the mentioned patent, also has the advantage that the price of printed follicles is likely to be so low within a short period of time after introduction that the process would be economically profitable for practitioners. The hope for a reliable therapy for alopecia, which is possible for everyone and affordable at the same time, is likely to generate a large number of interested parties for the approach.

However, the current facts should not be lost sight of: What is certain is that it is currently possible to assemble hair follicles in 3D printers from human cells that produce hair in previously naked mice after certain biochemical treatment steps. The mere spatial arrangement of the cells is not sufficient for this and the biochemical treatment steps cannot simply be repeated on the patient, since the side effects can be fatal, so that the efficiency of treatment on humans would probably be lower. In addition, there are fundamental differences in hair production between humans and rodents: Although human cells were transplanted into mice, no one can say with certainty what influence the experimental animals have on the procedure. There could be fundamental differences in the application of the procedure to humans and laboratory animals, which could lead to completely different results or even side effects, if the procedure was performed in humans in the same way.

Although the patent application, which covers the complete automation of the 3D printing of hair follicles including their transplantation, is an interesting step, some aspects are to be emphasized: The first is the legalformal side, according to which the patent protects the possible use of printed follicles with this method. However, this does not say anything about whether such an application is already possible to the extent described. For patent applicants, it is therefore primarily a matter of securing possible future profits from their invention. Secondly, the patent does not explain in a scientifically comprehensible way how exactly the treatment should be carried out, how the individual components of the experience were generated or how far the application on humans has been researched so far. The patent merely explains how such an application can take place. At the present time, it is therefore scientifically impossible to understand how far the development process of this treatment approach has actually progressed.

Conclusion

3-D printing processes now play an important role in medicine, especially when it comes to the artificial production of organs for which a suitable donor has yet to be found. The printed organs should be comparatively inexpensive, be available without limits and be suitable for everyone in principle. In addition to liver, heart and kidneys, that should be produced, the 3D printing of hair follicles for the treatment of hair loss has also become one focus of scientists in recent years.

It was quickly recognised that the spatial arrangement of the cells involved in the hair follicle is critical for hair production. With the help of scaffold structures, it was possible to keep the cells of the artificial hair follicles “in place” and even after the printed follicles had been transplanted into mice, they continued to produce hair. This recently led to the patenting of the fully automated treatment approach with printed follicles. It should be noted, however, that scientific reports currently only refer to experimental animals and that the methods used there cannot be transferred to humans, as this could have serious side effects. In this light, the patent must be regarded as protection of possible future economic interests and does not say anything about what is actually scientifically or technically feasible today.

Against this, it will probably take a few years before tried and tested approaches are developed which will make it possible to use printed follicles in a stable and economically viable way when it comes to treating alopecia. Until then, hair transplantation remains the only sustainable treatment approach if patients feel impaired by hair loss. Also with this method the patient and his individual characteristics have to be considered: What is possible, whether an own hair transplantation is possible and which treatment result can be expected, can only be clarified in a personal consultation. This personal care cannot replaced by any new treatment approach or automated process. If you are interested in a hair transplant, I would like to encourage you to contact me in order to arrange a personal consultation in our clinic.

Sincerely

Yours, Angela Lehmann

References

Abaci, H. E., Coffman, A., Doucet, Y., Chen, J., Jacków, J., Wang, E., … Christiano, A. M. (2018). Tissue engineering of human hair follicles using a biomimetic developmental approach. Nature communications, 9(1), 1–11.

Gnedeva, K., Vorotelyak, E., Cimadamore, F., Cattarossi, G., Giusto, E., Terskikh, V. V. & Terskikh, A. V. (2015). Derivation of hairinducing cell from human pluripotent stem cells. PLoS One, 10(1), e0116892.

Noor, N., Shapira, A., Edri, R., Gal, I., Wertheim, L. & Dvir, T. (2019). 3D Printing of Personalized Thick and Perfusable Cardiac Patches and Hearts. Advanced Science, 6, 1–10.

Sakin, M. & Kiroglu, Y. C. (2017). 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia, 134, 702–711.

US 2019 / 0275208 A1 (2019). Bioprinted Hair Follicles and Uses Therof. Online verfügbar unter: https://patents.google.com/patent/US20190275208A1/en [10.12.2019].